Home / Medical & Healthcare Equipment / Hospital Sanitaryware / Hospital Sinks / Slop Hoppers & Sluice Sinks / B22360(BG) Back-Entry Wall-Mounted Stainless Steel Slop Hopper with Grid

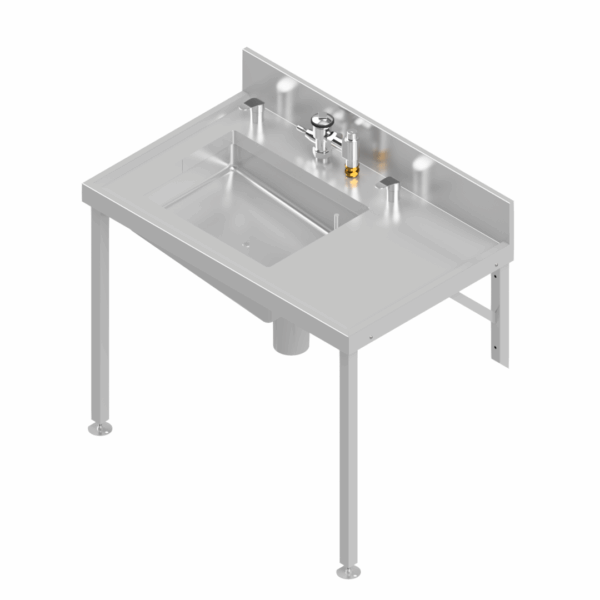

B22360(BG) Back-Entry Wall-Mounted Stainless Steel Slop Hopper with Grid

Built for healthcare and institutional use, this back-entry slop hopper is fabricated from AISI 304 stainless steel and designed for durability, hygiene, and ease of maintenance. Includes hinged grid and robust wall brackets. Flush valve not included — options available on request.

Lead Time:

± 10-15 working days

Categories: Slop Hoppers & Sluice Sinks, Sluice Room Equipment

Country of Origin: Manufactured in Johannesburg, South Africa

This wall-hung slop hopper is purpose-built for demanding environments such as hospitals, clinics, and high-traffic institutions. Manufactured from 1.2mm thick AISI 304 stainless steel, the unit features a pressed bowl with fully welded seams, providing a durable and hygienic solution for waste disposal. The entire assembly is polished to a satin finish, ensuring both corrosion resistance and ease of cleaning.

The B22360(BG) model is configured for back-entry flushing, offering flexible plumbing integration for retrofits or installations with concealed services. The flush valve is not supplied as standard with this unit, but compatible flush valve options (including manual and sensor types) can be specified upon request.

The hopper incorporates a hinged waste grid for convenience and is wall-mounted using heavy-duty 38 x 38mm stainless steel tubular gallow brackets for secure and long-lasting installation. The waste outlet is sized to accept a 100mm diameter trap, accommodating standard plumbing connections.

Key Features:

Grade: AISI 304 stainless steel

Thickness: 1.2mm

Finish: Satin polish for hygiene and corrosion resistance

Flushing Type: Back-entry configuration (flush valve optional)

Grid: Hinged at the rear for access and waste handling

Waste Outlet: Sized for 100mm diameter trap

Mounting: Wall-supported using 38 x 38mm stainless steel gallow brackets

Applications: Hospitals, aged-care facilities, clinics, public institutions

Flush Mechanism:

Not included by default. Compatible flush valve options available upon request.

Engineered for reliability in high-usage environments, the B22360(BG) model combines practical design with durable construction for long-term performance in sanitation-critical applications.

Locally Manufactured

Proudly manufactured in South Africa

Quick Production

Typical lead times of 10 - 15 working days

Product Customisations

Custom product specifications available

Not what you are looking for?

If this product isn’t exactly what you’re looking for, we may have other options. Our products are used in a variety of industries and applications, and we’d love to help you find the right fit.